Products Index

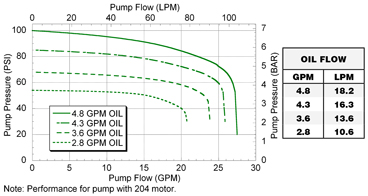

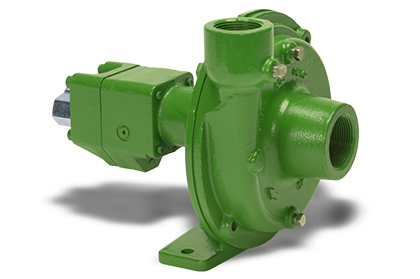

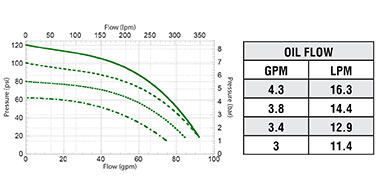

The 204 motor requires 4 GPM(15.1 LPM) maximum hydraulic fluid input. Recommended for:Pressure Compensating Closed Center Systems Open Center Systems up to 13 GPM (49.2 LPM) using internal needle valve bypass. The 206 motor requires 7 GPM (26.5 LPM) maximum hydraulic fluid input and fits virtually all tractor hydraulic systems. Recommended for:Pressure Compensating Closed Center Systems Load Sensing Closed Center Systems Open Center Systems up to 16 GPM (60.6 LPM) using internal needle valve bypass

1"

3/4"

SUCTION

DISCHARGE

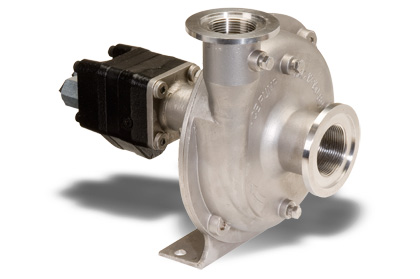

These compact corrosion resistant pumps are perfect for smaller transfer, spray, or tank rinsing applications.

Features:

Compact and light weight design Close coupled with separate pump and motor shafts for easy service All polypropylene construction with stainless steel internal hardware providing excellent corrosion resistance High efficiency, low flow hydraulic motors for efficient operation

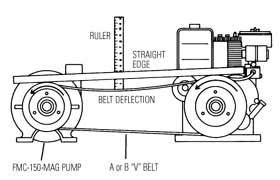

Pulley Ratio To get the desired performance from an ACE Frame Mounted Pump, the proper speed ratio between the pump and drive source must be established. The following link should be helpful: Pulley Ratio

Belt Alignment and Tension Proper belt alignment and belt tension will prevent premature bearing failure in the clutch and/or the pump. The following link should be helpful: Belt Adjustment

1-1/4

1

SUCTION

DISCHARGE

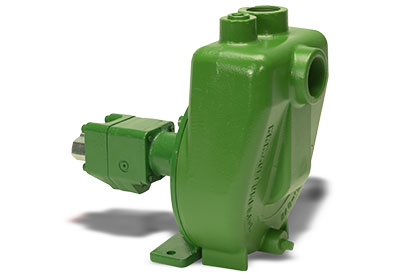

The farm industry standard since 1969. The 202 and 203 motors require 2 GPM (7.6 LPM) and 3 GPM (11.4 LPM) hydraulic fluid input. Recommended for engineered systems with limited oil flow. The 204 motor requires 4 GPM(15.1 LPM) maximum hydraulic fluid input. Recommended for:Pressure Compensating Closed Center Systems Open Center Systems up to 13 GPM (49.2 LPM) using internal needle valve bypass. The 206 motor requires 7 GPM (26.5 LPM) maximum hydraulic fluid input and fits virtually all tractor hydraulic systems. Recommended for:Pressure Compensating Closed Center Systems Load Sensing Closed Center Systems Open Center Systems up to 16 GPM (60.6 LPM) using internal needle valve bypass The 210 motor requires 10 GPM (37.9 LPM) maximum hydraulic fluid input. Recommended for:Load Sensing Closed Center Systems Open Center Systems up to 17 GPM (64.4 LPM) using internal needle valve bypass. The 310 motor requires 16 GPM (60.6 LPM) maximum hydraulic fluid input. Recommended for:Large Open Center Systems up to 24 GPM (90.9 LPM) using internal needle valve bypass. Optional 206 motor with integrated PWM (pulse width modulated) motor for precision applications

1-1/2

1-1/4

SUCTION

DISCHARGE

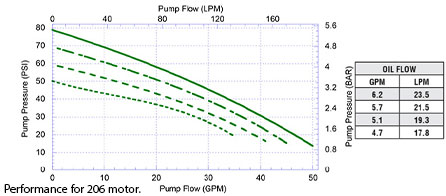

Provides higher pressure and greater volume for applications with large tanks and longer spray booms. The 206 motor requires 7 GPM (26.5 LPM) maximum hydraulic fluid input and fits virtually all tractor hydraulic systems. Recommended for:Pressure Compensating Closed Center Systems Load Sensing Closed Center Systems Open Center Systems up to 16 GPM (60.6 LPM) using internal needle valve bypass

220 Flange & 1-1/2"

200 Flange & 1-1/4"

SUCTION

DISCHARGE

F model equipped with NPT ports and industry standard flanged connections Provides higher pressure and greater volume for applications with large tanks and longer spray booms. The 206 motor requires 7 GPM (26.5 LPM) maximum hydraulic fluid input and fits virtually all tractor hydraulic systems. Recommended for:Pressure Compensating Closed Center Systems Load Sensing Closed Center Systems Open Center Systems up to 16 GPM (60.6 LPM) using internal needle valve bypass

Pump Rotation The direction of rotation is always determined WHEN FACING THE SHAFT. This rule applies for the pump shaft and the drive shaft. Ace Frame Mounted pumps are available in both clockwise (CW) and counterclockwise (CCW) rotation. Ace model numbers which include a “CW” have a clockwise rotation; all other models are counterclockwise rotation. The following link should be helpful: Pump Rotation

Multispeed die-cast quick coupler that fits 6-spline (540 RPM) and 21-spline (1,000 RPM) tractor PTOs for 5/8" or 15/16" shaft

Base plate for mounting -R version roller pumps to gas engine

Torque Bar Kit

220 Flange & 1-1/2"

200 Flange & 1-1/4"

SUCTION

DISCHARGE

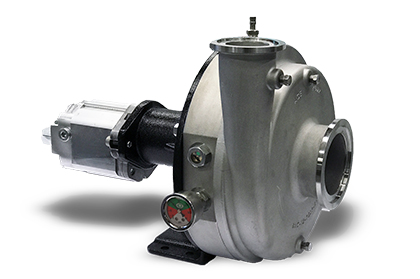

FS model constructed of 316 stainless steel with NPT ports and industry standard flanged connections Provides higher pressure and greater volume for applications with large tanks and longer spray booms. The 206 motor requires 7 GPM (26.5 LPM) maximum hydraulic fluid input and fits virtually all tractor hydraulic systems. Recommended for:Pressure Compensating Closed Center Systems Load Sensing Closed Center Systems Open Center Systems up to 16 GPM (60.6 LPM) using internal needle valve bypass

1-1/2

1-1/4

SUCTION

DISCHARGE

SP model is self-priming, making it perfect for load and spray applications Provides higher pressure and greater volume for applications with large tanks and longer spray booms. The 206 motor requires 7 GPM (26.5 LPM) maximum hydraulic fluid input and fits virtually all tractor hydraulic systems. Recommended for:Pressure Compensating Closed Center Systems Load Sensing Closed Center Systems Open Center Systems up to 16 GPM (60.6 LPM) using internal needle valve bypass

Run two products at the same time, at different rates.

Use only one SCV remote on your tractor.

Want to add PWM control to your existing pump with a 204 or 206 motor?

The Gemini DPK (Dual Pump Kit) was designed to solve these concerns. Pick any two pumps with 204 or 206 motors, and run them from one SCV remote port. Run them at different rates. Shut one pump off while leaving the other pump running. Have your rate controller send PWM signal to one or both of the pumps for precision application.

2

1-1/2

SUCTION

DISCHARGE

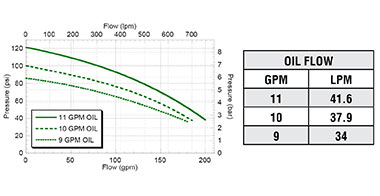

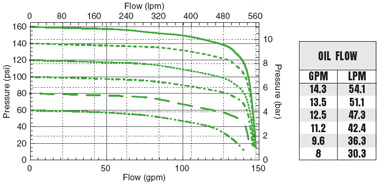

Ideal for spraying, large tank agitation, liquid transfer, and spray - transfer combinations The 210 motor requires 10 GPM (37.9 LPM) maximum hydraulic fluid input. Recommended for:Pressure Compensating Closed Center Systems Load Sensing Closed Center Systems Open Center Systems up to 17 GPM (64.4 LPM) using internal needle valve bypass The 304 motor requires 11 GPM (41.6 LPM) maximum hydraulic fluid input. Recommended for:Pressure Compensating Closed Center Systems Load Sensing Closed Center Systems Open Center Systems up to 20 GPM (75.7 LPM) using internal needle valve bypass The 310 motor requires 16 GPM (60.6 LPM) maximum hydraulic fluid input. Recommended for:Large Open Center Systems up to 24 GPM (90.9 LPM) using internal needle valve bypass.

2"

1-1/2"

SUCTION

DISCHARGE

Ideal for spraying, large tank agitation, liquid transfer, and spray - transfer combinations 316 Stainless Steel Wet End for superior corrosion resistance Optional motor with integrated PWM (pulse width modulated) motor for precision applications The 304 motor requires 11 GPM (41.6 LPM) maximum hydraulic fluid input. Recommended for:Pressure Compensating Closed Center Systems Load Sensing Closed Center Systems Open Center Systems up to 20 GPM (75.7 LPM) using internal needle valve bypass

300 Flange

220 Flange

SUCTION

DISCHARGE

F model equipped with industry standard flanged connections Ideal for spraying, large tank agitation, liquid transfer, and spray - transfer combinations The 304 motor requires 11 GPM (41.6 LPM) maximum hydraulic fluid input. Recommended for:Pressure Compensating Closed Center Systems Load Sensing Closed Center Systems Open Center Systems up to 20 GPM (75.7 LPM) using internal needle valve bypass

300 Flange

220 Flange

SUCTION

DISCHARGE

-F Model - Cast Iron housings Severe Duty Silicon Carbide Mechanical Seal with O-ring Seat for Improved Survivability Chemical Resistant Thermoplastic and optional Cast Iron or 316 Stainless Steel (FS models) available Optional motor with integrated PWM (pulse width modulated) motor for precision applications The 304 motor requires 11 GPM (41.6 LPM) maximum hydraulic fluid input. Recommended for:Pressure Compensating Closed Center Systems Load Sensing Closed Center Systems Open Center Systems up to 20 GPM (75.7 LPM) using internal needle valve bypass

300 Flange

220 Flange

SUCTION

DISCHARGE

-FS Model - 316 Stainless Steel Wet End Severe Duty Silicon Carbide Mechanical Seal with O-ring Seat for Improved Survivability Chemical Resistant Thermoplastic and optional Cast Iron or 316 Stainless Steel (FS models) available Optional motor with integrated PWM (pulse width modulated) motor for precision applications The 304 motor requires 11 GPM (41.6 LPM) maximum hydraulic fluid input. Recommended for:

Pressure Compensating Closed Center Systems Load Sensing Closed Center Systems Open Center Systems up to 20 GPM (75.7 LPM) using internal needle valve bypass

1-1/4"

1"

SUCTION

DISCHARGE

E-Coated cast iron housings for added corrosion resistance Larger bearings provide longer life Severe duty silicon carbide seal standard - resists abrasive scratching and transfers heat away from seal faces for improved survival during short run-dry events The 204 motor requires 4 GPM(15.1 LPM) maximum hydraulic fluid input. Recommended for:Pressure Compensating Closed Center Systems Open Center Systems up to 13 GPM (49.2 LPM) using internal needle valve bypass. The 206 motor requires 7 GPM (26.5 LPM) maximum hydraulic fluid input and fits virtually all tractor hydraulic systems. Recommended for:Pressure Compensating Closed Center Systems Load Sensing Closed Center Systems Open Center Systems up to 16 GPM (60.6 LPM) using internal needle valve bypass

220 Flange & 1-1/2"

200 Flange & 1-1/4"

SUCTION

DISCHARGE

E-Coated cast iron housings for added corrosion resistance Larger bearings provide longer life Severe duty silicon carbide seal standard - resists abrasive scratching and transfers heat away from seal faces for improved survival during short run-dry events Optional motor with integrated PWM (pulse width modulated) motor for precision applications The 206 motor requires 7 GPM (26.5 LPM) maximum hydraulic fluid input and fits virtually all tractor hydraulic systems.Pressure Compensating Closed Center Systems Load Sensing Closed Center Systems Open Center Systems up to 16 GPM (60.6 LPM) using internal needle valve bypass The 304 motor requires 11 GPM (41.6 LPM) maximum hydraulic fluid input. Recommended for:

Pressure Compensating Closed Center Systems Load Sensing Closed Center Systems Open Center Systems up to 20 GPM (75.7 LPM) using internal needle valve bypass

1-1/4"

1"

SUCTION

DISCHARGE

E-Coated cast iron housings for added corrosion resistance Larger bearings provide longer life Ace Pump's exclusive Oasis WetSeal Technology Optional motor with integrated PWM (pulse width modulated) motor for precision applications The 204 motor requires 4 GPM(15.1 LPM) maximum hydraulic fluid input.Pressure Compensating Closed Center Systems Open Center Systems up to 13 GPM (49.2 LPM) using internal needle valve bypass. The 206 motor requires 7 GPM (26.5 LPM) maximum hydraulic fluid input and fits virtually all tractor hydraulic systems.Pressure Compensating Closed Center Systems Load Sensing Closed Center Systems Open Center Systems up to 16 GPM (60.6 LPM) using internal needle valve bypass

220 Flange & 1-1/2"

200 Flange & 1-1/4"

SUCTION

DISCHARGE

E-Coated cast iron housings for added corrosion resistance Larger bearings provide longer life Ace Pump’s exclusive Oasis WetSeal Technology Optional motor with integrated PWM (pulse width modulated) motor for precision applications The 206 motor requires 7 GPM (26.5 LPM) maximum hydraulic fluid input and fits virtually all tractor hydraulic systems.Pressure Compensating Closed Center Systems Load Sensing Closed Center Systems Open Center Systems up to 16 GPM (60.6 LPM) using internal needle valve bypass The 304 motor requires 11 GPM (41.6 LPM) maximum hydraulic fluid input. Recommended for:Pressure Compensating Closed Center Systems Load Sensing Closed Center Systems Open Center Systems up to 20 GPM (75.7 LPM) using internal needle valve bypass

1 1/2

1 1/4

SUCTION

DISCHARGE

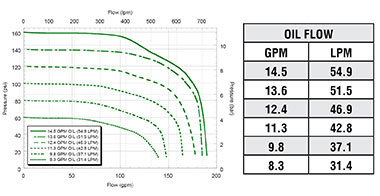

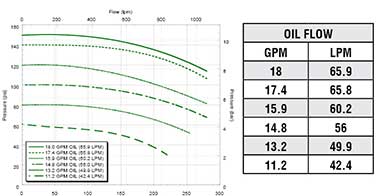

Modified impeller design develops higher pressure at lower RPM. Durable E-Coat finish provides extra corrosion resistance on all surfaces inside and out. Oversized bearings for extended pump life. Splined motor to pump shaft connection strengthens the power train while allowing for easy repair and maintenance. 4000 PSI high efficiency pressure plated gear motor provides higher output with less oil flow. The M16 motor requires 14 GPM (53 LPM) maximum hydraulic fluid input. Recommended for:Pressure Compensating Closed Center Systems Load Sensing Closed Center Systems Open Center Systems up to 14 GPM (53 LPM)

220 Flange & 1-1/2"

200 Flange & 1-1/4"

SUCTION

DISCHARGE

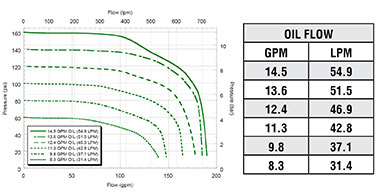

Modified impeller design develops higher pressure at lower RPM. F model equipped with NPT ports and industry standard flanged connections. Durable E-Coat finish provides extra corrosion resistance on all surfaces inside and out. Oversized bearings for extended pump life. Splined motor to pump shaft connection strengthens the power train while allowing for easy repair and maintenance. 4000 PSI high efficiency pressure plated gear motor provides higher output with less oil flow. Optional motor with integrated PWM (pulse width modulated) motor for precision applications The M16 motor requires 14 GPM (53 LPM) maximum hydraulic fluid input. Recommended for:Pressure Compensating Closed Center Systems Load Sensing Closed Center Systems Open Center Systems up to 14 GPM (53 LPM)

220 Flange & 1-1/2"

200 Flange & 1-1/4"

SUCTION

DISCHARGE

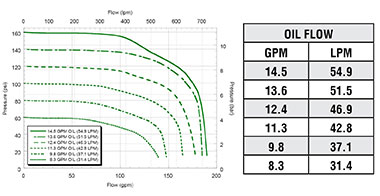

Modified impeller design develops higher pressure at lower RPM. F model equipped with NPT ports and industry standard flanged connections. Durable E-Coat finish provides extra corrosion resistance on all surfaces inside and out. Oversized bearings for extended pump life. Splined motor to pump shaft connection strengthens the power train while allowing for easy repair and maintenance. 4000 PSI high efficiency pressure plated gear motor provides higher output with less oil flow. Optional motor with integrated PWM (pulse width modulated) motor for precision applications The M16 motor requires 14 GPM (53 LPM) maximum hydraulic fluid input. Recommended for:Pressure Compensating Closed Center Systems Load Sensing Closed Center Systems Open Center Systems up to 14 GPM (53 LPM)

220 Flange & 1-1/2"

200 Flange & 1-1/4"

SUCTION

DISCHARGE

Modified impeller design develops higher pressure at lower RPM. F model equipped with NPT ports and industry standard flanged connections. Durable E-Coat finish provides extra corrosion resistance on all surfaces inside and out. Oversized bearings for extended pump life. Splined motor to pump shaft connection strengthens the power train while allowing for easy repair and maintenance. 4000 PSI high efficiency pressure plated gear motor provides higher output with less oil flow. Ace Pump’s exclusive Oasis WetSeal Technology Optional motor with integrated PWM (pulse width modulated) motor for precision applications The M16 motor requires 14 GPM (53 LPM) maximum hydraulic fluid input. Recommended for:Pressure Compensating Closed Center Systems Load Sensing Closed Center Systems Open Center Systems up to 14 GPM (53 LPM)

220 Flange & 1-1/2"

200 Flange & 1-1/4"

SUCTION

DISCHARGE

Modified impeller design develops higher pressure at lower RPM. F model equipped with NPT ports and industry standard flanged connections. Durable E-Coat finish provides extra corrosion resistance on all surfaces inside and out. Oversized bearings for extended pump life. Splined motor to pump shaft connection strengthens the power train while allowing for easy repair and maintenance. 4000 PSI high efficiency pressure plated gear motor provides higher output with less oil flow. Ace Pump’s exclusive Oasis WetSeal Technology Optional motor with integrated PWM (pulse width modulated) motor for precision applications The M16 motor requires 14 GPM (53 LPM) maximum hydraulic fluid input. Recommended for:Pressure Compensating Closed Center Systems Load Sensing Closed Center Systems Open Center Systems up to 14 GPM (53 LPM)

300 Flange

220 Flange

SUCTION

DISCHARGE

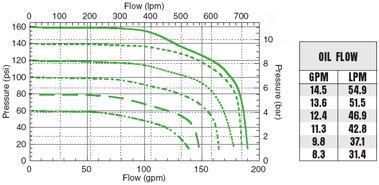

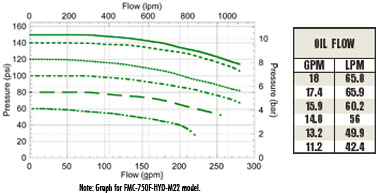

Pressure balanced impeller eliminates thrust load on bearings. Standard industry flanged ports for higher flow. Optional M22 motor with integrated PWM (pulse width modulated) motor for precision applications The M22 motor requires 18 GPM (65.8 LPM) maximum hydraulic fluid input. Recommended for:Pressure Compensating Closed Center Systems Load Sensing Closed Center Systems Open Center Systems up to 18 GPM (65.8 LPM) The M25 motor requires 20 GPM (75.7 LPM) maximum hydraulic fluid input. Recommended for:Pressure Compensating Closed Center Systems Load Sensing Closed Center Systems Open Center Systems up to 20 GPM (75.7 LPM)

300

220

SUCTION

DISCHARGE

Maximum Flow = 290 GPM (1098 LPM) Maximum Pressure = 150 PSI (10.3 BAR) Operates at Lower RPM E-Coat Corrosion Protection High Efficiency 4000 PSI (275 BAR) Pressure Plated Gear Motor Optional M22 motor with integrated PWM (pulse width modulated) motor for precision applications Optional Case Drain Available The M22 motor requires 18 GPM (65.8 LPM) maximum hydraulic fluid input. Recommended for:Pressure Compensating Closed Center Systems Load Sensing Closed Center Systems Open Center Systems up to 18 GPM (65.8 LPM) The M25 motor requires 20 GPM (75.7 LPM) maximum hydraulic fluid input. Recommended for:Pressure Compensating Closed Center Systems Load Sensing Closed Center Systems Open Center Systems up to 20 GPM (75.7 LPM)

300 Flange

300 Flange

SUCTION

DISCHARGE

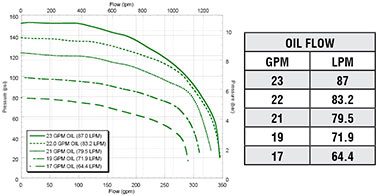

Pressure balanced impeller eliminates thrust load on bearings. Standard industry flanged ports for higher flow. The M30 motor requires 23 GPM (87 LPM) maximum hydraulic fluid input. Recommended for:Pressure Conpensating Closed Center Systems Load Sensing Closed Center Systems Open Center Systems up to 23 GPM (87 LPM)

1-1/4

1

SUCTION

DISCHARGE

The original belt drive standard since 1964 Time tested and field proven design Widespread parts and service availability Most Economical belt drive MAXIMUM PRESSURE: 80 PSI (5.5 BAR) MAXIMUM FLOW: 65 GPM (246 LPM) PTOC-600 PTOC-1000

-6SP -6SPQC -21SP -20SP -B Standard 1-3/8" (34.9mm) 6 spline shaft for 540 RPM PTO Models Optional instant-attach quick coupler feature for 540 RPM PTO models Standard 21 spline 1-3/8" (34.9mm) split bore shaft with locking collar for 1000 RPM PTO models 20 spline 1-3/4" (44.5mm) split bore shaft with locking collar for larger 1000 RPM PTO Models 1" (25.4mm) stub shaft for installation on trailer sprayers driven by PTO tumblerod

Tall Blade Impeller design - higher pressure at standard engine speeds Impeller attaches directly to 5/8" (1.59 cm) keyed shaft engine All Polypropylene corrosion resistant construction Available complete or less engine GE-75-HONDA MAXIMUM PRESSURE: 70 PSI (4.8 BAR) MAXIMUM FLOW: 25 GPM (95 LPM)

Tall Blade Impeller design - higher pressure at standard engine speeds Impeller attaches directly to 3/4" (1.91 cm) keyed shaft engine All Polypropylene corrosion resistant construction GE-85-HONDA MAXIMUM PRESSURE: 65 PSI (4.5 BAR) MAXIMUM FLOW: 24 GPM (91 LPM)

1"

3/4"

SUCTION

DISCHARGE

Self-Priming up to 6 feet (1.8 meters) Tall Blade Impeller design - higher pressure at standard engine speeds Impeller attaches directly to 3/4" (1.91 cm) keyed shaft engine All Polypropylene corrosion resistant construction Available less engine or complete with engine

1-1/4

1

SUCTION

DISCHARGE

Impeller attaches directly to 5/8" (1.59 cm) NF threaded shaft on 3 HP (2.8 KW) to 5.5 HP (4.1 KW) engine Stainless steel shaft sleeve with o-ring leak protection All iron construction Available complete or less engine MAXIMUM PRESSURE: 50 PSI (3.5 BAR) MAXIMUM FLOW: 50 GPM (189 LPM)

1-1/2

1-1/4

SUCTION

DISCHARGE

GE-650 Features Impeller attaches directly to 5/8" (1.59 cm) NF threaded shaft on 5.5 HP (4.1 KW) engine Stainless steel shaft sleeve with o-ring leak protection All iron construction Available complete or less engine GE-660 Features Impeller attaches directly to 3/4" (1. 91cm) keyed shaft on 5.5 HP (4.1 KW) engine Stainless steel shaft sleeve with o-ring leak protection All iron housings with thermoplastic impeller Optional cast iron impeller available Available complete or less engine MAXIMUM PRESSURE: 120 PSI (8.3 BAR) MAXIMUM FLOW: 110 GPM (416 LPM)

2

1-1/2

SUCTION

DISCHARGE

GE-800 Features Impeller attaches directly to 1 " (2.54 cm) - 14 NF threaded shaft on 8 HP (5.9 KW) to 10 HP (7.5 KW) engine Stainless steel shaft sleeve with o-ring leak protection All iron construction Available complete or less engine GE-860 Features Impeller attaches directly to 1 " (2.54 cm) keyed shaft on 8 HP (5.9 KW) to 10 HP (7.5 KW) engine Optional electric start engine All iron construction Available complete or less engine MAXIMUM PRESSURE: 140 PSI (9.7 BAR) MAXIMUM FLOW: 140 GPM (530 LPM)

2-1/2

2

SUCTION

DISCHARGE

Impeller attaches directly to 1" (2.54 cm) - 14 NF threaded shaft on 16 HP (12 KW) to 20 HP (15 KW) engine Standard 16 HP (12 KW) electric start engine Stainless steel shaft sleeve with double o-ring leak protection All iron construction Available complete or less engine MAXIMUM PRESSURE: 120 PSI (8.3 BAR) MAXIMUM FLOW: 280 GPM (1060 LPM)

General Advantages ACE/VALVTEC™ ball valves are the premium valves for critical uses. The valves are available with ratchet or quarter turn handle designs. ACE/VALVTEC™ puts the durability of metal where performance counts.

Standard valve features include: Unique diagonally split valve body for easy cleaning and service Ratchet on/off or quarter turn operation Rugged all-metal bodies in cast iron, aluminum, or bronze Hard chrome plated or stainless steel balls Standard and full flow models Withstand working pressures up to 400 PSI (27.6 BAR) Series 16 Standard Port Valves Available with 1/4-turn handle or ratchet handle. An open-closed indicator is provided with ratchet handle model. Operation of ratchet handle may be cable, chain, cord, or push-pull rod. Available in cast iron, aluminum, or bronze. Choice of hard chrome plated carbon steel balls or stainless balls. Size range 1/2" to 3".

58 ft. lb. (78.6 NM) torque capacity Forged machined pulley for maximum strength Solid forged rotor to maximize torque High temperature epoxy coil Two clutch bearings with high temperature, long life grease Single or double belt drive 4-3/4" pitch diameter

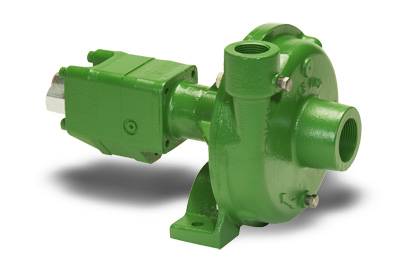

3/4" (1.91cm) Diameter stainless steel shaft (standard models 5/8" diameter) (1.59 cm) Larger bearings for extended life Available with MAG-D clutch 5-1/4" (13.34 cm) mounting bolt spacing X3 frame has 3" (7.62 cm) bolt spacing

1-1/4

1

SUCTION

DISCHARGE

Counterclockwise Rotation when facing shaft end Stainless Steel Shaft and Wear Ring Chemical resistant Valox® or optional cast iron impeller Standard Viton® Carbon/Ceramic seal or optional Severe Duty Silicon Carbide Mechanical seal MAG-D models equipped with heavy 12V clutch MAXIMUM PRESSURE: 170 PSI (11.7 BAR) MAXIMUM FLOW: 70 GPM (265 LPM) MAXIMUM POWER: 4.2 HP (3.1 KW)

1-1/2

1-1/4

SUCTION

DISCHARGE

Counterclockwise Rotation when facing shaft end Stainless Steel Shaft and Wear Ring Chemical resistant Valox® or optional cast iron impeller Standard Viton® Carbon/Ceramic seal or optional Severe Duty Silicon Carbide Mechanical seal SP model is self-priming, making it perfect for load and spray applications MAG-D models equipped with heavy 12V clutch MAXIMUM PRESSURE: 130 PSI (9 BAR) MAXIMUM FLOW: 130 GPM (492 LPM) MAXIMUM POWER: 10 HP (7.5 KW)

1-1/2

1-1/4

SUCTION

DISCHARGE

Modified impeller design develops higher pressure at lower RPM. E-Coat protection for excellent corrosion resistance. Standard Viton® Carbon/Ceramic seal or optional Severe Duty Silicon Carbide Mechanical seal. MAXIMUM PRESSURE: 160 PSI (11 BAR) MAXIMUM FLOW: 140 GPM (530 LPM) MAXIMUM POWER: 22 HP (16.4 KW)

220 Flange

200 Flange

SUCTION

DISCHARGE

Modified impeller design develops higher pressure at lower RPM. F model equipped with NPT ports and industry standard flanged connections. E-Coat protection for excellent corrosion resistance. Standard Viton® Carbon/Ceramic seal or optional Severe Duty Silicon Carbide Mechanical seal. MAXIMUM PRESSURE: 160 PSI (11 BAR) MAXIMUM FLOW: 170 GPM (643 LPM) MAXIMUM POWER: 22 HP (16.4 KW)

1-1/2

1-1/4

SUCTION

DISCHARGE

Modified impeller design develops higher pressure at lower RPM E-Coat protection for excellent corrosion resistance Standard Viton® Carbon/Ceramic seal or optional Severe Duty Silicon Carbide Mechanical seal MAG-D models equipped with heavy duty 12V clutch MAXIMUM PRESSURE: 160 PSI (11 BAR) MAXIMUM FLOW: 140 GPM (530 LPM) MAXIMUM POWER: 22 HP (16.4 KW)

220 Flange

200 Flange

SUCTION

DISCHARGE

Modified impeller design develops higher pressure at lower RPM F model equipped with NPT ports and industry standard flanged connections E-Coat protection for excellent corrosion resistance Standard Viton® Carbon/Ceramic seal or optional Severe Duty Silicon Carbide Mechanical seal MAG-D models equipped with heavy duty 12V clutch MAXIMUM PRESSURE: 160 PSI (11 BAR) MAXIMUM FLOW: 170 GPM (643 LPM) MAXIMUM POWER: 22 HP (16.4 KW)

2

1-1/2

SUCTION

DISCHARGE

Counterclockwise Rotation when facing shaft end Stainless Steel Shaft and Wear Ring Chemical resistant Valox® or optional cast iron impeller Standard Viton® Carbon/Ceramic seal or optional Severe Duty Silicon Carbide Mechanical seal MAG-D models equipped with heavy 12V clutch MAXIMUM PRESSURE: 120 PSI (8.3 BAR) MAXIMUM FLOW: 200 GPM (757 LPM) MAXIMUM POWER: 7.5 HP (5.6 KW)

1"

3/4"

SUCTION

DISCHARGE

Compact and light weight design All polypropylene construction with stainless steel internal hardware providing excellent corrosion resistance Self-priming up to 6 ft. (1.8 m) For belt driven applications Clockwise rotation when viewed from shaft end

1-1/4

1

SUCTION

DISCHARGE

Clockwise Rotation when facing shaft end Stainless Steel Shaft and Wear Ring Chemical resistant Valox® or optional cast iron impeller Standard Viton® Carbon/Ceramic seal or optional Severe Duty Silicon Carbide Mechanical seal MAG-D models equipped with heavy 12V clutch MAXIMUM PRESSURE: 170 PSI (11.7 BAR) MAXIMUM FLOW: 70 GPM (265 LPM) MAXIMUM POWER: 4.2 HP (3.1 KW)

1-1/2

1-1/4

SUCTION

DISCHARGE

Clockwise Rotation when facing shaft end Stainless Steel Shaft and Wear Ring Chemical resistant Valox® or optional cast iron impeller Standard Viton® Carbon/Ceramic seal or optional Severe Duty Silicon Carbide Mechanical seal MAG-D models equipped with heavy 12V clutch X3 model has 3-1/2" (8.89 cm) spacing on mounting base; all other models have 5-1/4" (13.34 cm) DX3 model for Spra-Coupe® Models: 3430, 3440, 3630, 3640, 4440, 4640 MAXIMUM PRESSURE: 120 PSI (8.3 BAR) MAXIMUM FLOW: 80 GPM (303 LPM) MAXIMUM POWER: 4.7 HP (3.5 KW)

1-1/2

1-1/4

SUCTION

DISCHARGE

Clockwise Rotation when facing shaft end Modified impeller design develops higher pressure at lower RPM E-Coat protection for excellent corrosion resistance Standard Viton® Carbon/Ceramic seal or optional Severe Duty Silicon Carbide Mechanical seal MAXIMUM PRESSURE: 160 PSI (11 BAR) MAXIMUM FLOW: 140 GPM (530 LPM) MAXIMUM POWER: 22 HP (16.4 KW)

1-1/2

1-1/4

SUCTION

DISCHARGE

Clockwise Rotation when facing shaft end Modified impeller design develops higher pressure at lower RPM E-Coat protection for excellent corrosion resistance Standard Viton® Carbon/Ceramic seal or optional Severe Duty Silicon Carbide Mechanical seal MAG-D models equipped with heavy duty 12V clutch MAXIMUM PRESSURE: 160 PSI (11 BAR) MAXIMUM FLOW: 140 GPM (530 LPM) MAXIMUM POWER: 22 HP (16.4 KW)

2

1-1/2

SUCTION

DISCHARGE

Clockwise Rotation when facing shaft end Stainless Steel Shaft and Wear Ring Chemical resistant Valox® or optional cast iron impeller Standard Viton® Carbon/Ceramic seal or optional Severe Duty Silicon Carbide Mechanical seal MAG-D models equipped with heavy 12V clutch MAXIMUM PRESSURE: 120 PSI (8.3 BAR) MAXIMUM FLOW: 200 GPM (757 LPM) MAXIMUM POWER: 7.5 HP (5.6 KW)

2

1-1/2

SUCTION

DISCHARGE

Large diameter impeller provides higher pressure at slower speeds Easily replaceable mechanical seal Clockwise Rotation when facing shaft end Stainless Steel Shaft All iron construction Heavy-duty double row ball bearings Standard Viton® Carbon/Ceramic seal or optional Severe Duty Silicon Carbide Mechanical seal MAXIMUM PRESSURE: 170 PSI (11.7 BAR) MAXIMUM FLOW: 180 GPM (681 LPM) MAXIMUM POWER: 14.2 HP (10.6 KW)

1-1/4

1

SUCTION

DISCHARGE

MAXIMUM PRESSURE: 30 PSI (2.1 BAR) MAXIMUM FLOW: 40 GPM (151 LPM) For most industrial and agricultural blending, mixing, seed treating and liquid transfer applications. Easily replaceable Viton® mechanical seal Non-overloading 3/4 HP (0.56 KW) 3450 RPM single phase totally enclosed fan cooled electric motor, for use in all dusty, dirty or weather exposed locations Optional silicone carbide seal available for abrasive solutions Chemical resistant Valox® or optional cast iron impeller

3/4

3/4

SUCTION

DISCHARGE

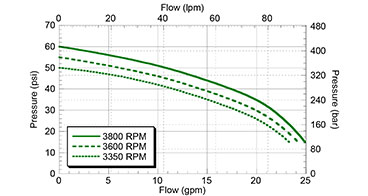

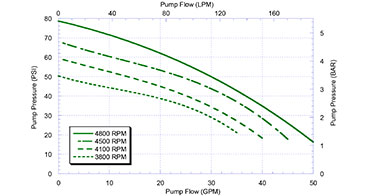

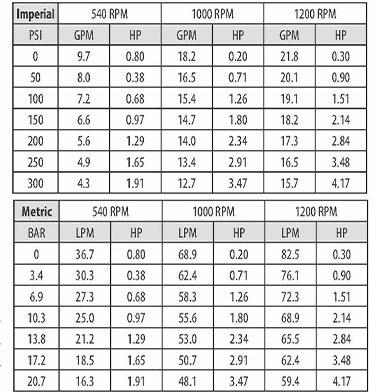

Maximum Flow = 21.8 GPM (82.5 LPM) Maximum Pressure = 300 PSI (20.7 BAR) Speeds from 540 to 1200 RPM 5/8" Stainless Steel Shaft Counter-Clockwise rotation standard “-R” clockwise rotation available Bulk packaged option available for manufacturers

3/4

3/4

SUCTION

DISCHARGE

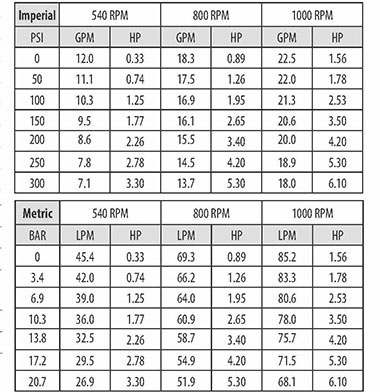

Maximum Flow = 22.5 GPM (85.2 LPM) Maximum Pressure = 300 PSI (20.7 BAR) Speeds from 540 to 1000 RPM 15/16" Stainless Steel Shaft Counter-Clockwise rotation standard “-R” clockwise rotation available Bulk packaged option available for manufacturers

Product Sheet

Product Sheet

Instruction Manual

Instruction Manual

Product Sheet

Product Sheet

Product Sheet

Product Sheet Product Sheet

Product Sheet Product Sheet

Product Sheet Product Sheet

Product Sheet Product Sheet

Product Sheet Setup Sheet

Setup Sheet Instruction Manual

Instruction Manual 210 Product Sheet

210 Product Sheet Product Sheet

Product Sheet Product Sheet

Product Sheet Product Sheet

Product Sheet PWM Product Sheet

PWM Product Sheet PWM Product Sheet

PWM Product Sheet Product Sheet

Product Sheet Motor Sheet

Motor Sheet Product Sheet

Product Sheet Product Sheet

Product Sheet Product Sheet

Product Sheet Product Sheet

Product Sheet Instruction Manual

Instruction Manual Product Sheet

Product Sheet Product Sheet

Product Sheet Product Sheet

Product Sheet Product Sheet

Product Sheet Product Sheet

Product Sheet Product Sheet

Product Sheet Instruction Manual

Instruction Manual Product Sheet

Product Sheet Product Sheet

Product Sheet Product Sheet

Product Sheet Product Sheet

Product Sheet Product Sheet

Product Sheet Product Sheet - GE-650

Product Sheet - GE-650 Product Sheet - GE-800

Product Sheet - GE-800 Product Sheet

Product Sheet Product Sheet - FMC

Product Sheet - FMC Product Sheet - FMC-150

Product Sheet - FMC-150 Product Sheet - FMC-150-MAG-D

Product Sheet - FMC-150-MAG-D Product Sheet - FMC-200

Product Sheet - FMC-200 Product Sheet - FMC-200-MAG-DX

Product Sheet - FMC-200-MAG-DX Product Sheet

Product Sheet Product Sheet - FMC-CW

Product Sheet - FMC-CW Product Sheet - FMC-CW-MAG-D

Product Sheet - FMC-CW-MAG-D Product Sheet - FMC-CW-150

Product Sheet - FMC-CW-150 Product Sheet - FMC-CW-150-X

Product Sheet - FMC-CW-150-X Product Sheet - FMC-CW-150-MAG-D

Product Sheet - FMC-CW-150-MAG-D Product Sheet - FMC-CW-200

Product Sheet - FMC-CW-200 Product Sheet - FMC-CW-200-X

Product Sheet - FMC-CW-200-X Product Sheet - FMC-CW-800-DRB

Product Sheet - FMC-CW-800-DRB Product Sheet - FMC-CW-800-MAG-D

Product Sheet - FMC-CW-800-MAG-D Product Sheet

Product Sheet Product Sheet

Product Sheet Manual

Manual Product Sheet

Product Sheet