Belt Driven Centrifugal Pumps

General Advantages

Frame Mount Advantages

Ace belt driven pumps are available in a variety of models which can be belt driven or direct coupled to a power source. The pumps are available in either clockwise or counterclockwise rotation. The standard bare shaft pumps are designed with a keyway for mounting a drive pulley or coupling.

Magnetic Clutch Driven Advantages

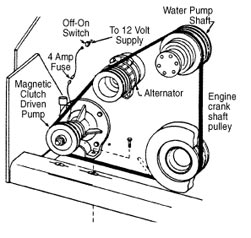

The integral magnetic clutch driven centrifugal pump design was first offered by Ace in 1982. These models enabled the operator to free the PTO shaft and hydraulic system for other uses. The 12 volt DC magnetic clutch is driven by a v-belt from the engine drive shaft. The clutch is idle until engaged by an on-off toggle switch located at the driver’s seat.

Typical Clutch Installation

Ace magnetic clutch driven frame mounted centrifugal pump models are available with counterclockwise (CCW) rotation and clockwise (CW) rotation. The direction of rotation is determined when facing the shaft. Sizes available are 1-1/4" x 1", 1-1/2" x 1-1/4", and 2" x 1-1/2".

MAG-D Clutch

- 58 ft. lb. (78.6 NM) torque capacity

- Forged machined pulley for maximum strength

- Solid forged rotor to maximize torque

- High temperature epoxy coil

- Two clutch bearings with high temperature, long life grease

- Single or double belt drive

- 4-3/4" pitch diameter

X Frame Option

- 3/4" (1.91cm) Diameter stainless steel shaft (standard models 5/8" diameter) (1.59 cm)

- Larger bearings for extended life

- Available with MAG-D clutch

- 5-1/4" (13.34 cm) mounting bolt spacing

- X3 frame has 3" (7.62 cm) bolt spacing

Pulley Ratio

To get the desired performance from an ACE Frame Mounted Pump, the proper speed ratio between the pump and drive source must be established. The following link should be helpful: Pulley Ratio.

Belt Alignment and Tension

Proper belt alignment and belt tension will prevent premature bearing failure in the clutch and/or the pump. The following link should be helpful: Belt Adjustment.

FMC | FMC-MAG-D

| SUCTION | DISCHARGE |

|---|---|

| 1-1/4 NPT | 1 NPT |

- Counterclockwise Rotation when facing shaft end

- Stainless Steel Shaft and Wear Ring

- Chemical resistant Valox® or optional cast iron impeller

- Standard Viton® Carbon/Ceramic seal or optional Severe Duty Silicon Carbide Mechanical seal

- MAG-D models equipped with heavy 12V clutch

MAXIMUM PRESSURE: 170 PSI (11.7 BAR)

MAXIMUM FLOW: 70 GPM (265 LPM) MAXIMUM POWER: 4.2 HP (3.1 KW)

FMC-150 | FMC-150SP | FMC-150-MAG-D | FMC-150SP-MAG-D

| SUCTION | DISCHARGE |

|---|---|

| 1-1/2 NPT | 1-1/4 NPT |

- Counterclockwise Rotation when facing shaft end

- Stainless Steel Shaft and Wear Ring

- Chemical resistant Valox® or optional cast iron impeller

- Standard Viton® Carbon/Ceramic seal or optional Severe Duty Silicon Carbide Mechanical seal

- SP model is self-priming, making it perfect for load and spray applications

- MAG-D models equipped with heavy 12V clutch

MAXIMUM PRESSURE: 130 PSI (9 BAR)

MAXIMUM FLOW: 130 GPM (492 LPM) MAXIMUM POWER: 10 HP (7.5 KW)

FMC-650-MAG-D

| SUCTION | DISCHARGE |

|---|---|

| 1-1/2 NPT | 1-1/4 NPT |

- Modified impeller design develops higher pressure at lower RPM

- E-Coat protection for excellent corrosion resistance

- Standard Viton® Carbon/Ceramic seal or optional Severe Duty Silicon Carbide Mechanical seal

- MAG-D models equipped with heavy duty 12V clutch

MAXIMUM PRESSURE: 160 PSI (11 BAR)

MAXIMUM FLOW: 140 GPM (530 LPM)

MAXIMUM POWER: 22 HP (16.4 KW)

Pump Rotation

The direction of rotation is always determined WHEN FACING THE SHAFT. This rule applies for the pump shaft and the drive shaft. Ace Frame Mounted pumps are available in both clockwise (CW) and counterclockwise (CCW) rotation. Ace model numbers which include a “CW” have a clockwise rotation; all other models are counterclockwise rotation. The following link should be helpful: Pump Rotation.

FMC-650F-MAG-D

| SUCTION | DISCHARGE |

|---|---|

| 220 Flange | 200 Flange |

- Modified impeller design develops higher pressure at lower RPM

- F model equipped with NPT ports and industry standard flanged connections

- E-Coat protection for excellent corrosion resistance

- Standard Viton® Carbon/Ceramic seal or optional Severe Duty Silicon Carbide Mechanical seal

- MAG-D models equipped with heavy duty 12V clutch

MAXIMUM PRESSURE: 160 PSI (11 BAR)

MAXIMUM FLOW: 170 GPM (643 LPM)

MAXIMUM POWER: 22 HP (16.4 KW)

FMC-200 | FMC-200-MAG-D

| SUCTION | DISCHARGE |

|---|---|

| 2 NPT | 1-1/2 NPT |

- Counterclockwise Rotation when facing shaft end

- Stainless Steel Shaft and Wear Ring

- Chemical resistant Valox® or optional cast iron impeller

- Standard Viton® Carbon/Ceramic seal or optional Severe Duty Silicon Carbide Mechanical seal

- MAG-D models equipped with heavy 12V clutch

MAXIMUM PRESSURE: 120 PSI (8.3 BAR)

MAXIMUM FLOW: 200 GPM (757 LPM) MAXIMUM POWER: 7.5 HP (5.6 KW)

FMC-CW-75SP

| SUCTION | DISCHARGE |

|---|---|

| 1 NPT | 3/4 NPT |

- Compact and light weight design

- All polypropylene construction with stainless steel internal hardware providing excellent corrosion resistance

- Self-priming up to 6 ft. (1.8 m)

- For belt driven applications

- Clockwise rotation when viewed from shaft end

FMC-CW | FMC-CW-MAG-D

| SUCTION | DISCHARGE |

|---|---|

| 1-1/4 NPT | 1 NPT |

- Clockwise Rotation when facing shaft end

- Stainless Steel Shaft and Wear Ring

- Chemical resistant Valox® or optional cast iron impeller

- Standard Viton® Carbon/Ceramic seal or optional Severe Duty Silicon Carbide Mechanical seal

- MAG-D models equipped with heavy 12V clutch

MAXIMUM PRESSURE: 170 PSI (11.7 BAR)

MAXIMUM FLOW: 70 GPM (265 LPM)

MAXIMUM POWER: 4.2 HP (3.1 KW)

FMC-CW-150 | FMC-CW-150-MAG-D | FMC-CW-150-MAG-DX3

| SUCTION | DISCHARGE |

|---|---|

| 1-1/2 NPT | 1-1/4 NPT |

- Clockwise Rotation when facing shaft end

- Stainless Steel Shaft and Wear Ring

- Chemical resistant Valox® or optional cast iron impeller

- Standard Viton® Carbon/Ceramic seal or optional Severe Duty Silicon Carbide Mechanical seal

- MAG-D models equipped with heavy 12V clutch

- X3 model has 3-1/2" (8.89 cm) spacing on mounting base; all other models have 5-1/4" (13.34 cm)

- DX3 model for Spra-Coupe® Models: 3430, 3440, 3630, 3640, 4440, 4640

MAXIMUM PRESSURE: 120 PSI (8.3 BAR)

MAXIMUM FLOW: 80 GPM (303 LPM)

MAXIMUM POWER: 4.7 HP (3.5 KW)

FMC-CW-650-MAG-D

| SUCTION | DISCHARGE |

|---|---|

| 1-1/2 NPT | 1-1/4 NPT |

- Clockwise Rotation when facing shaft end

- Modified impeller design develops higher pressure at lower RPM

- E-Coat protection for excellent corrosion resistance

- Standard Viton® Carbon/Ceramic seal or optional Severe Duty Silicon Carbide Mechanical seal

- MAG-D models equipped with heavy duty 12V clutch

MAXIMUM PRESSURE: 160 PSI (11 BAR)

MAXIMUM FLOW: 140 GPM (530 LPM)

MAXIMUM POWER: 22 HP (16.4 KW)

FMC-CW-200 | FMC-CW-200-MAG-D

| SUCTION | DISCHARGE |

|---|---|

| 2 NPT | 1-1/2 NPT |

- Clockwise Rotation when facing shaft end

- Stainless Steel Shaft and Wear Ring

- Chemical resistant Valox® or optional cast iron impeller

- Standard Viton® Carbon/Ceramic seal or optional Severe Duty Silicon Carbide Mechanical seal

- MAG-D models equipped with heavy 12V clutch

MAXIMUM PRESSURE: 120 PSI (8.3 BAR)

MAXIMUM FLOW: 200 GPM (757 LPM)

MAXIMUM POWER: 7.5 HP (5.6 KW)

FMC-CW-800 | FMC-CW-800-MAG-D

| SUCTION | DISCHARGE |

|---|---|

| 2 NPT | 1-1/2 NPT |

- Large diameter impeller provides higher pressure at slower speeds

- Easily replaceable mechanical seal

- Clockwise Rotation when facing shaft end

- Stainless Steel Shaft

- All iron construction

- Heavy-duty double row ball bearings

- Standard Viton® Carbon/Ceramic seal or optional Severe Duty Silicon Carbide Mechanical seal

MAXIMUM PRESSURE: 170 PSI (11.7 BAR)

MAXIMUM FLOW: 180 GPM (681 LPM)

MAXIMUM POWER: 14.2 HP (10.6 KW)