Application Information

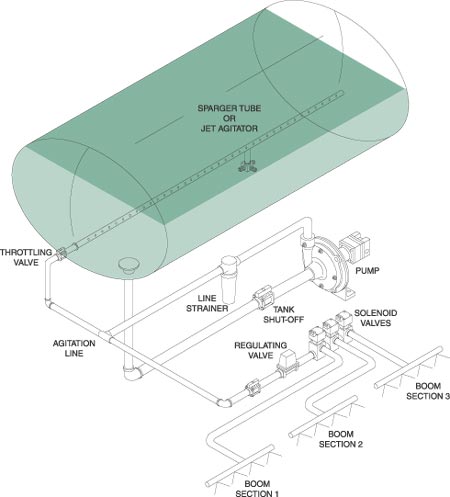

Sprayer Plumbing Suggestions

The primary goal when plumbing a sprayer pump is to route liquid from the pump to the spray boom with minimum restriction. Minimizing restrictions is necessary for achieving the pump's maximum rated capacity.

- Hoses should be the same size as the pump's suction and discharge ports.

- Install a pressure gauge and valve on the discharge side of the pump for the purpose of measuring the SHUT-OFF pressure.

- A minimum number of elbows, fittings, and valves should be used to reduce pressure losses.

- Avoid locating electronic spray control valves between the pump and boom. Following these guidelines is necessary for delivering the highest pressures to the boom.

Pump Mounting

The following are basic guidelines for proper pump mounting:

- The pump should be mounted below the tanks to allow gravity to naturally fill the pump with liquid.

- The volute should be oriented with the discharge port pointing up or across the top of the pump which allows air to rise out of the pump.

- A petcock valve may be installed in the top most pipe plug hole to allow air to be bled off each time the tanks are filled.

- Another option would be to install a 1/8” air bleed line from the top most pipe plug hole to the sprayer tank. This will continually bleed air from the pump housing.

- If the pump must be located above the liquid level, a check valve should be installed to maintain the pump's prime.

ACE centrifugal pumps are straight centrifugals and must be primed prior to operation. The word "primed" means the pump must be completely full of water and any trapped air vented before operation. Following the pump mounting guidelines will insure proper priming of the pump and avoid premature seal failure.