Products Index

General Advantages

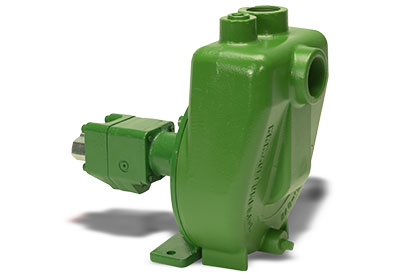

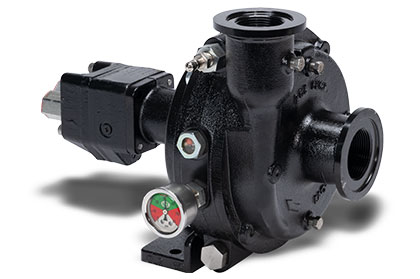

Ace developed the first hydraulic motor driven pump at the request of John Deere in 1969. Many of the original pumps are still operating today after more than 30 years of service.

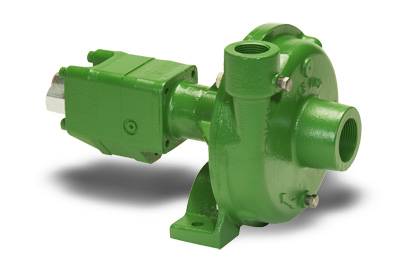

Centrifugal pump design provides good resistance to abrasive solutions and extra flow for agitation. The advantages of the hydraulic motor driven pump are mounting versatility, customized performance, and ease of maintenance. All hydraulic driven pumps are equipped with a stainless steel shaft and wear ring for excellent corrosion resistance.

- MOUNTING VERSATILITY: The location of the pump is not tied to the PTO or engine drive shaft; the pump can be mounted in a variety of locations to suit application requirements.

- CUSTOMIZED PERFORMANCE: The performance is dependent on the supply of hydraulic oil to the motor and not necessarily tied to engine speed. A hydraulic driven pump can produce higher pressures than PTO or belt driven pumps. They can also hold constant pressure at varying engine speeds on closed center hydraulic systems.

- EASY MAINTENANCE: On a hydraulic driven pump there are no belts to align or break. Separate pump and hydraulic motor shafts simplify repair and replacement. Two main pump bearings support shaft loads. All pumps are equipped with easily replaceable FKM mechanical seals.

The Ace gear type hydraulic motor is more efficient than gerotor type motors, and is less subject to damage by contamination than the gerotor design. A built-in needle valve allows for the bypass of up to 9 GPM excess hydraulic fluid on open center systems. The standard motor has a reverse flow check valve which prevents backward hookup and a coasting check which protects the motor seal from the flywheel effect of the impeller. A restrictor orifice is included with pump models recommended for pressure compensating closed center systems. The Ace Internet Hydraulic Selection Guide is here to help in finding the proper hydraulic pump for your tractor.

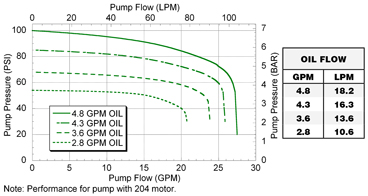

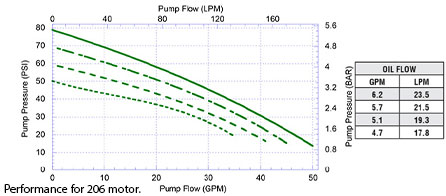

FMC-75-HYD-204 FMC-75-HYD-206

| 1 | 3/4 |

| SUCTION | DISCHARGE |

|---|

- The 204 motor requires 4 GPM(15.1 LPM) maximum hydraulic fluid input. Recommended for:

- Pressure Compensating Closed Center Systems

- Open Center Systems up to 13 GPM (49.2 LPM) using internal needle valve bypass.

- The 206 motor requires 7 GPM (26.5 LPM) maximum hydraulic fluid input and fits virtually all tractor hydraulic systems. Recommended for:

- Pressure Compensating Closed Center Systems

- Load Sensing Closed Center Systems

- Open Center Systems up to 16 GPM (60.6 LPM) using internal needle valve bypass

FMC-75SP-HYD-204 | FMC-75SP-HYD-206 | FMC-75SP-HYD-206-PWM

| 1" | 3/4" |

| SUCTION | DISCHARGE |

|---|

These compact corrosion resistant pumps are perfect for smaller transfer, spray, or tank rinsing applications.

Features:

- Compact and light weight design

- Close coupled with separate pump and motor shafts for easy service

- All polypropylene construction with stainless steel internal hardware providing excellent corrosion resistance

- High efficiency, low flow hydraulic motors for efficient operation

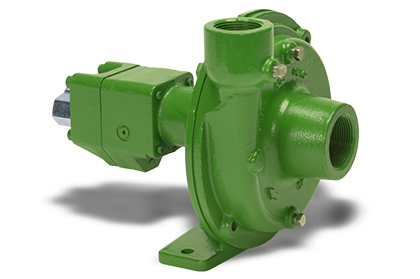

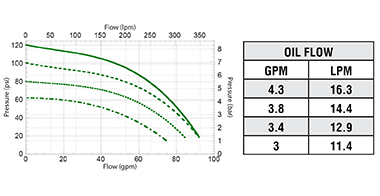

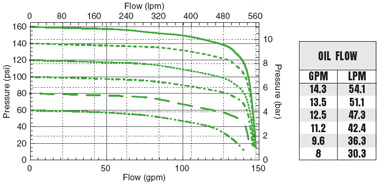

FMC-HYD-202 FMC-HYD-203 FMC-HYD-204

FMC-HYD-206 FMC-HYD-210 FMC-HYD-310

| 1-1/4 | 1 |

| SUCTION | DISCHARGE |

|---|

- The farm industry standard since 1969.

- The 202 and 203 motors require 2 GPM (7.6 LPM) and 3 GPM (11.4 LPM) hydraulic fluid input. Recommended for engineered systems with limited oil flow.

- The 204 motor requires 4 GPM(15.1 LPM) maximum hydraulic fluid input. Recommended for:

- Pressure Compensating Closed Center Systems

- Open Center Systems up to 13 GPM (49.2 LPM) using internal needle valve bypass.

- The 206 motor requires 7 GPM (26.5 LPM) maximum hydraulic fluid input and fits virtually all tractor hydraulic systems. Recommended for:

- Pressure Compensating Closed Center Systems

- Load Sensing Closed Center Systems

- Open Center Systems up to 16 GPM (60.6 LPM) using internal needle valve bypass

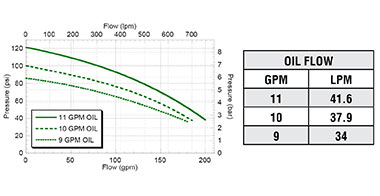

- The 210 motor requires 10 GPM (37.9 LPM) maximum hydraulic fluid input. Recommended for:

- Load Sensing Closed Center Systems

- Open Center Systems up to 17 GPM (64.4 LPM) using internal needle valve bypass.

- The 310 motor requires 16 GPM (60.6 LPM) maximum hydraulic fluid input. Recommended for:

- Large Open Center Systems up to 24 GPM (90.9 LPM) using internal needle valve bypass.

- Optional 206 motor with integrated PWM (pulse width modulated) motor for precision applications

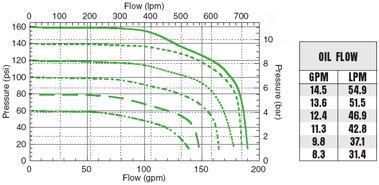

FMC-150-HYD-206

| 1-1/2 | 1-1/4 |

| SUCTION | DISCHARGE |

|---|

- Provides higher pressure and greater volume for applications with large tanks and longer spray booms.

- The 206 motor requires 7 GPM (26.5 LPM) maximum hydraulic fluid input and fits virtually all tractor hydraulic systems. Recommended for:

- Pressure Compensating Closed Center Systems

- Load Sensing Closed Center Systems

- Open Center Systems up to 16 GPM (60.6 LPM) using internal needle valve bypass

FMC-150F-HYD-206

| 220 Flange & 1-1/2" | 200 Flange & 1-1/4" |

| SUCTION | DISCHARGE |

|---|

- F model equipped with NPT ports and industry standard flanged connections

- Provides higher pressure and greater volume for applications with large tanks and longer spray booms.

- The 206 motor requires 7 GPM (26.5 LPM) maximum hydraulic fluid input and fits virtually all tractor hydraulic systems. Recommended for:

- Pressure Compensating Closed Center Systems

- Load Sensing Closed Center Systems

- Open Center Systems up to 16 GPM (60.6 LPM) using internal needle valve bypass

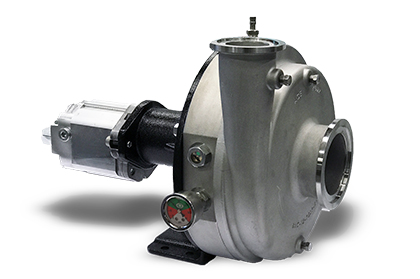

FMC-150FS-HYD-206

| 220 Flange & 1-1/2" | 200 Flange & 1-1/4" |

| SUCTION | DISCHARGE |

|---|

- FS model constructed of 316 stainless steel with NPT ports and industry standard flanged connections

- Provides higher pressure and greater volume for applications with large tanks and longer spray booms.

- The 206 motor requires 7 GPM (26.5 LPM) maximum hydraulic fluid input and fits virtually all tractor hydraulic systems. Recommended for:

- Pressure Compensating Closed Center Systems

- Load Sensing Closed Center Systems

- Open Center Systems up to 16 GPM (60.6 LPM) using internal needle valve bypass

FMC-150SP-HYD-206

| 1-1/2 | 1-1/4 |

| SUCTION | DISCHARGE |

|---|

- SP model is self-priming, making it perfect for load and spray applications

- Provides higher pressure and greater volume for applications with large tanks and longer spray booms.

- The 206 motor requires 7 GPM (26.5 LPM) maximum hydraulic fluid input and fits virtually all tractor hydraulic systems. Recommended for:

- Pressure Compensating Closed Center Systems

- Load Sensing Closed Center Systems

- Open Center Systems up to 16 GPM (60.6 LPM) using internal needle valve bypass

Gemini Dual Pump Kit

| SUCTION | DISCHARGE |

|---|

Run two products at the same time, at different rates.

Use only one SCV remote on your tractor.

Want to add PWM control to your existing pump with a 204 or 206 motor?

The Gemini DPK (Dual Pump Kit) was designed to solve these concerns. Pick any two pumps with 204 or 206 motors, and run them from one SCV remote port. Run them at different rates. Shut one pump off while leaving the other pump running. Have your rate controller send PWM signal to one or both of the pumps for precision application.

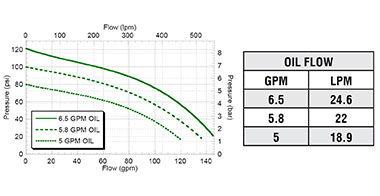

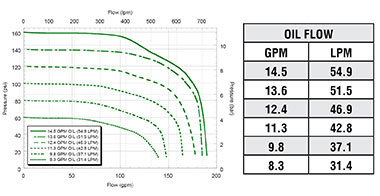

FMC-200-HYD-210

FMC-200-HYD-304 FMC-200-HYD-310

| 2 | 1-1/2 |

| SUCTION | DISCHARGE |

|---|

- Ideal for spraying, large tank agitation, liquid transfer, and spray - transfer combinations

- The 210 motor requires 10 GPM (37.9 LPM) maximum hydraulic fluid input. Recommended for:

- Pressure Compensating Closed Center Systems

- Load Sensing Closed Center Systems

- Open Center Systems up to 17 GPM (64.4 LPM) using internal needle valve bypass

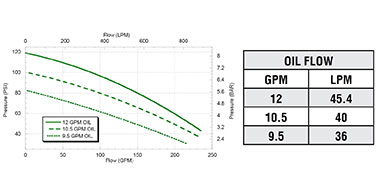

- The 304 motor requires 11 GPM (41.6 LPM) maximum hydraulic fluid input. Recommended for:

- Pressure Compensating Closed Center Systems

- Load Sensing Closed Center Systems

- Open Center Systems up to 20 GPM (75.7 LPM) using internal needle valve bypass

- The 310 motor requires 16 GPM (60.6 LPM) maximum hydraulic fluid input. Recommended for:

- Large Open Center Systems up to 24 GPM (90.9 LPM) using internal needle valve bypass.

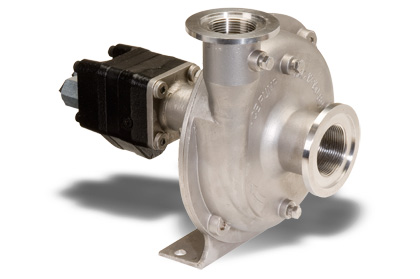

FMC-200SS-HYD-304

| 2" | 1-1/2" |

| SUCTION | DISCHARGE |

|---|

- Ideal for spraying, large tank agitation, liquid transfer, and spray - transfer combinations

- 316 Stainless Steel Wet End for superior corrosion resistance

- Optional motor with integrated PWM (pulse width modulated) motor for precision applications

- The 304 motor requires 11 GPM (41.6 LPM) maximum hydraulic fluid input. Recommended for:

- Pressure Compensating Closed Center Systems

- Load Sensing Closed Center Systems

- Open Center Systems up to 20 GPM (75.7 LPM) using internal needle valve bypass

FMC-200F-HYD-304

| 300 Flange | 220 Flange |

| SUCTION | DISCHARGE |

|---|

- F model equipped with industry standard flanged connections

- Ideal for spraying, large tank agitation, liquid transfer, and spray - transfer combinations

- The 304 motor requires 11 GPM (41.6 LPM) maximum hydraulic fluid input. Recommended for:

- Pressure Compensating Closed Center Systems

- Load Sensing Closed Center Systems

- Open Center Systems up to 20 GPM (75.7 LPM) using internal needle valve bypass

FMCSC-205F-HYD-304 FMCSC-205F-HYD-304-PWM

| 300 Flange | 220 Flange |

| SUCTION | DISCHARGE |

|---|

- -F Model - Cast Iron housings

- Severe Duty Silicon Carbide Mechanical Seal with O-ring Seat for Improved Survivability

- Chemical Resistant Thermoplastic and optional Cast Iron or 316 Stainless Steel (FS models) available

- Optional motor with integrated PWM (pulse width modulated) motor for precision applications

- The 304 motor requires 11 GPM (41.6 LPM) maximum hydraulic fluid input. Recommended for:

- Pressure Compensating Closed Center Systems

- Load Sensing Closed Center Systems

- Open Center Systems up to 20 GPM (75.7 LPM) using internal needle valve bypass

FMCSC-205FS-HYD-304 FMCSC-205FS-HYD-304-PWM

| 300 Flange | 220 Flange |

| SUCTION | DISCHARGE |

|---|

- -FS Model - 316 Stainless Steel Wet End

- Severe Duty Silicon Carbide Mechanical Seal with O-ring Seat for Improved Survivability

- Chemical Resistant Thermoplastic and optional Cast Iron or 316 Stainless Steel (FS models) available

- Optional motor with integrated PWM (pulse width modulated) motor for precision applications

- The 304 motor requires 11 GPM (41.6 LPM) maximum hydraulic fluid input.

Recommended for:

- Pressure Compensating Closed Center Systems

- Load Sensing Closed Center Systems

- Open Center Systems up to 20 GPM (75.7 LPM) using internal needle valve bypass

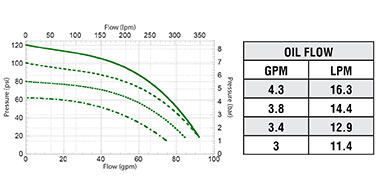

FMCSC-125-HYD-204 FMCSC-125-HYD-206 FMCSC-125-HYD-206-PWM

| 1-1/4" | 1" |

| SUCTION | DISCHARGE |

|---|

- E-Coated cast iron housings for added corrosion resistance

- Larger bearings provide longer life

- Severe duty silicon carbide seal standard - resists abrasive scratching and transfers heat away from seal faces for improved survival during short run-dry events

- The 204 motor requires 4 GPM(15.1 LPM) maximum hydraulic fluid input. Recommended for:

- Pressure Compensating Closed Center Systems

- Open Center Systems up to 13 GPM (49.2 LPM) using internal needle valve bypass.

- The 206 motor requires 7 GPM (26.5 LPM) maximum hydraulic fluid input and fits virtually all tractor hydraulic systems. Recommended for:

- Pressure Compensating Closed Center Systems

- Load Sensing Closed Center Systems

- Open Center Systems up to 16 GPM (60.6 LPM) using internal needle valve bypass

FMCSC-155F-HYD-206 FMCSC-155F-HYD-304

FMCSC-155F-HYD-206-PWM FMCSC-155F-HYD-304-PWM

| 220 Flange & 1-1/2" | 200 Flange & 1-1/4" |

| SUCTION | DISCHARGE |

|---|

- E-Coated cast iron housings for added corrosion resistance

- Larger bearings provide longer life

- Severe duty silicon carbide seal standard - resists abrasive scratching and transfers heat away from seal faces for improved survival during short run-dry events

- Optional motor with integrated PWM (pulse width modulated) motor for precision applications

- The 206 motor requires 7 GPM (26.5 LPM) maximum hydraulic fluid input and fits virtually all tractor hydraulic systems.

- Pressure Compensating Closed Center Systems

- Load Sensing Closed Center Systems

- Open Center Systems up to 16 GPM (60.6 LPM) using internal needle valve bypass

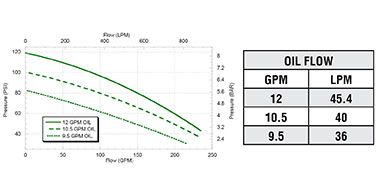

- The 304 motor requires 11 GPM (41.6 LPM) maximum hydraulic fluid input.

Recommended for:

- Pressure Compensating Closed Center Systems

- Load Sensing Closed Center Systems

- Open Center Systems up to 20 GPM (75.7 LPM) using internal needle valve bypass

FMCWS-125-HYD-204 FMCWS-125-HYD-206 FMCWS-125-HYD-206-PWM

| 1-1/4" | 1" |

| SUCTION | DISCHARGE |

|---|

- E-Coated cast iron housings for added corrosion resistance

- Larger bearings provide longer life

- Ace Pump's exclusive Oasis WetSeal Technology

- Optional motor with integrated PWM (pulse width modulated) motor for precision applications

- The 204 motor requires 4 GPM(15.1 LPM) maximum hydraulic fluid input.

- Pressure Compensating Closed Center Systems

- Open Center Systems up to 13 GPM (49.2 LPM) using internal needle valve bypass.

- The 206 motor requires 7 GPM (26.5 LPM) maximum hydraulic fluid input and fits virtually all tractor hydraulic systems.

- Pressure Compensating Closed Center Systems

- Load Sensing Closed Center Systems

- Open Center Systems up to 16 GPM (60.6 LPM) using internal needle valve bypass

FMCWS-155F-HYD-206 FMCWS-155F-HYD-304

FMCWS-155F-HYD-206-PWM FMCWS-155F-HYD-304-PWM

| 220 Flange & 1-1/2" | 200 Flange & 1-1/4" |

| SUCTION | DISCHARGE |

|---|

- E-Coated cast iron housings for added corrosion resistance

- Larger bearings provide longer life

- Ace Pump’s exclusive Oasis WetSeal Technology

- Optional motor with integrated PWM (pulse width modulated) motor for precision applications

- The 206 motor requires 7 GPM (26.5 LPM) maximum hydraulic fluid input and fits virtually all tractor hydraulic systems.

- Pressure Compensating Closed Center Systems

- Load Sensing Closed Center Systems

- Open Center Systems up to 16 GPM (60.6 LPM) using internal needle valve bypass

- The 304 motor requires 11 GPM (41.6 LPM) maximum hydraulic fluid input. Recommended for:

- Pressure Compensating Closed Center Systems

- Load Sensing Closed Center Systems

- Open Center Systems up to 20 GPM (75.7 LPM) using internal needle valve bypass

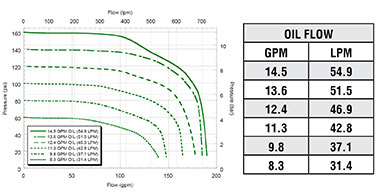

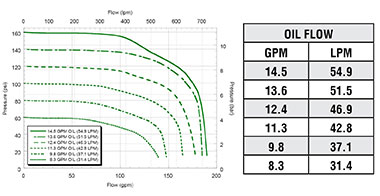

FMC-650-HYD

| 1 1/2 | 1 1/4 |

| SUCTION | DISCHARGE |

|---|

- Modified impeller design develops higher pressure at lower RPM.

- Durable E-Coat finish provides extra corrosion resistance on all surfaces inside and out.

- Oversized bearings for extended pump life.

- Splined motor to pump shaft connection strengthens the power train while allowing for easy repair and maintenance.

- 4000 PSI high efficiency pressure plated gear motor provides higher output with less oil flow.

- The M16 motor requires 14 GPM (53 LPM) maximum hydraulic fluid input. Recommended for:

- Pressure Compensating Closed Center Systems

- Load Sensing Closed Center Systems

- Open Center Systems up to 14 GPM (53 LPM)

FMC-650F-HYD FMC-650F-HYD-PWM

| 220 Flange & 1-1/2" | 200 Flange & 1-1/4" |

| SUCTION | DISCHARGE |

|---|

- Modified impeller design develops higher pressure at lower RPM.

- F model equipped with NPT ports and industry standard flanged connections.

- Durable E-Coat finish provides extra corrosion resistance on all surfaces inside and out.

- Oversized bearings for extended pump life.

- Splined motor to pump shaft connection strengthens the power train while allowing for easy repair and maintenance.

- 4000 PSI high efficiency pressure plated gear motor provides higher output with less oil flow.

- Optional motor with integrated PWM (pulse width modulated) motor for precision applications

- The M16 motor requires 14 GPM (53 LPM) maximum hydraulic fluid input. Recommended for:

- Pressure Compensating Closed Center Systems

- Load Sensing Closed Center Systems

- Open Center Systems up to 14 GPM (53 LPM)

FMC-650FS-HYD FMC-650FS-HYD-PWM

| 220 Flange & 1-1/2" | 200 Flange & 1-1/4" |

| SUCTION | DISCHARGE |

|---|

- Modified impeller design develops higher pressure at lower RPM.

- F model equipped with NPT ports and industry standard flanged connections.

- Durable E-Coat finish provides extra corrosion resistance on all surfaces inside and out.

- Oversized bearings for extended pump life.

- Splined motor to pump shaft connection strengthens the power train while allowing for easy repair and maintenance.

- 4000 PSI high efficiency pressure plated gear motor provides higher output with less oil flow.

- Optional motor with integrated PWM (pulse width modulated) motor for precision applications

- The M16 motor requires 14 GPM (53 LPM) maximum hydraulic fluid input. Recommended for:

- Pressure Compensating Closed Center Systems

- Load Sensing Closed Center Systems

- Open Center Systems up to 14 GPM (53 LPM)

FMCWS-650F-HYD FMCWS-650F-HYD-PWM

| 220 Flange & 1-1/2" | 200 Flange & 1-1/4" |

| SUCTION | DISCHARGE |

|---|

- Modified impeller design develops higher pressure at lower RPM.

- F model equipped with NPT ports and industry standard flanged connections.

- Durable E-Coat finish provides extra corrosion resistance on all surfaces inside and out.

- Oversized bearings for extended pump life.

- Splined motor to pump shaft connection strengthens the power train while allowing for easy repair and maintenance.

- 4000 PSI high efficiency pressure plated gear motor provides higher output with less oil flow.

- Ace Pump’s exclusive Oasis WetSeal Technology

- Optional motor with integrated PWM (pulse width modulated) motor for precision applications

- The M16 motor requires 14 GPM (53 LPM) maximum hydraulic fluid input.

- Recommended for:

- Pressure Compensating Closed Center Systems

- Load Sensing Closed Center Systems

- Open Center Systems up to 14 GPM (53 LPM)

FMCWS-650FS-HYD FMCWS-650FS-HYD-PWM

| 220 Flange & 1-1/2" | 200 Flange & 1-1/4" |

| SUCTION | DISCHARGE |

|---|

- Modified impeller design develops higher pressure at lower RPM.

- F model equipped with NPT ports and industry standard flanged connections.

- Durable E-Coat finish provides extra corrosion resistance on all surfaces inside and out.

- Oversized bearings for extended pump life.

- Splined motor to pump shaft connection strengthens the power train while allowing for easy repair and maintenance.

- 4000 PSI high efficiency pressure plated gear motor provides higher output with less oil flow.

- Ace Pump’s exclusive Oasis WetSeal Technology

- Optional motor with integrated PWM (pulse width modulated) motor for precision applications

- The M16 motor requires 14 GPM (53 LPM) maximum hydraulic fluid input. Recommended for:

- Pressure Compensating Closed Center Systems

- Load Sensing Closed Center Systems

- Open Center Systems up to 14 GPM (53 LPM)

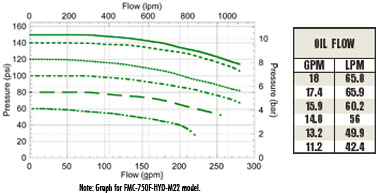

FMC-750F-HYD-M22 FMC-750F-HYD-M25

FMC-750F-HYD-M22-PWM

| 300 Flange | 220 Flange |

| SUCTION | DISCHARGE |

|---|

- Pressure balanced impeller eliminates thrust load on bearings.

- Standard industry flanged ports for higher flow.

- Optional M22 motor with integrated PWM (pulse width modulated) motor for precision applications

- The M22 motor requires 18 GPM (65.8 LPM) maximum hydraulic fluid input. Recommended for:

- Pressure Compensating Closed Center Systems

- Load Sensing Closed Center Systems

- Open Center Systems up to 18 GPM (65.8 LPM)

- The M25 motor requires 20 GPM (75.7 LPM) maximum hydraulic fluid input. Recommended for:

- Pressure Compensating Closed Center Systems

- Load Sensing Closed Center Systems

- Open Center Systems up to 20 GPM (75.7 LPM)

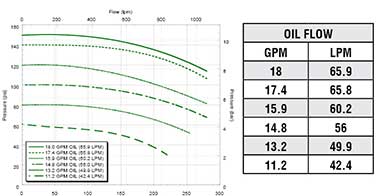

FMC-755FS-HYD-M22 FMC-755FS-HYD-M25

FMC-755FS-HYD-M22-PWM

| 300 | 220 |

| SUCTION | DISCHARGE |

|---|

- Maximum Flow = 290 GPM (1098 LPM)

- Maximum Pressure = 150 PSI (10.3 BAR)

- Operates at Lower RPM

- E-Coat Corrosion Protection

- High Efficiency 4000 PSI (275 BAR) Pressure Plated Gear Motor

- Optional M22 motor with integrated PWM (pulse width modulated) motor for precision applications

- Optional Case Drain Available

- The M22 motor requires 18 GPM (65.8 LPM) maximum hydraulic fluid input. Recommended for:

- Pressure Compensating Closed Center Systems

- Load Sensing Closed Center Systems

- Open Center Systems up to 18 GPM (65.8 LPM)

- The M25 motor requires 20 GPM (75.7 LPM) maximum hydraulic fluid input. Recommended for:

- Pressure Compensating Closed Center Systems

- Load Sensing Closed Center Systems

- Open Center Systems up to 20 GPM (75.7 LPM)

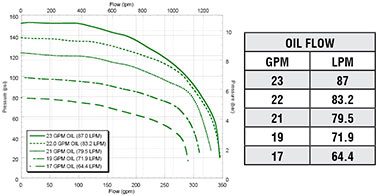

FMC-855F-HYD

| 300 Flange | 300 Flange |

| SUCTION | DISCHARGE |

|---|

- Pressure balanced impeller eliminates thrust load on bearings.

- Standard industry flanged ports for higher flow.

- The M30 motor requires 23 GPM (87 LPM) maximum hydraulic fluid input. Recommended for:

- Pressure Conpensating Closed Center Systems

- Load Sensing Closed Center Systems

- Open Center Systems up to 23 GPM (87 LPM)

Product Sheet

Product Sheet

Instruction Manual

Instruction Manual

Product Sheet

Product Sheet

Product Sheet

Product Sheet Product Sheet

Product Sheet Product Sheet

Product Sheet Product Sheet

Product Sheet Product Sheet

Product Sheet Setup Sheet

Setup Sheet Instruction Manual

Instruction Manual 210 Product Sheet

210 Product Sheet Product Sheet

Product Sheet Product Sheet

Product Sheet Product Sheet

Product Sheet PWM Product Sheet

PWM Product Sheet PWM Product Sheet

PWM Product Sheet Product Sheet

Product Sheet Motor Sheet

Motor Sheet Product Sheet

Product Sheet Product Sheet

Product Sheet Product Sheet

Product Sheet Product Sheet

Product Sheet Instruction Manual

Instruction Manual Product Sheet

Product Sheet Product Sheet

Product Sheet Product Sheet

Product Sheet Product Sheet

Product Sheet Product Sheet

Product Sheet